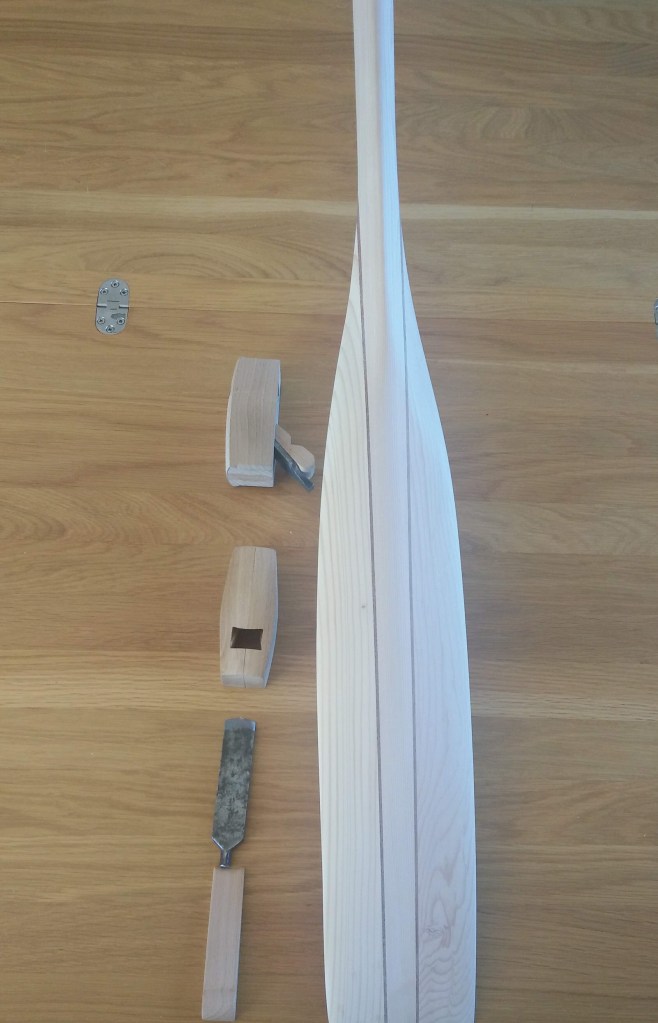

Oars

Bench Vice

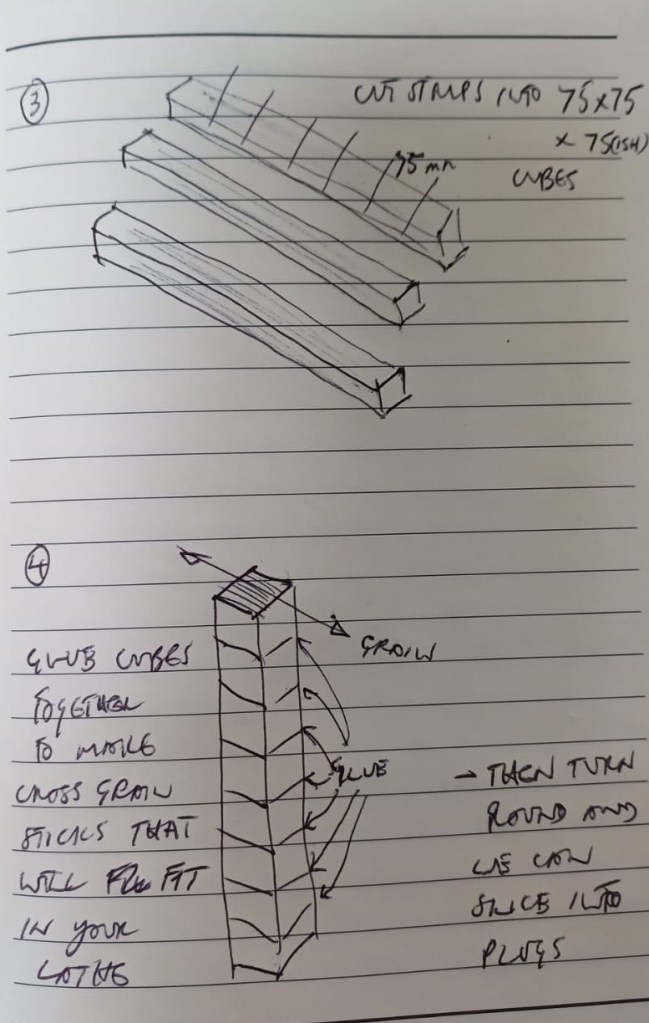

Tree Nails

I was looking at “planking” a boat using tree nails as fasteners so that seemed a good excuse to use up some off cut Oak and turn a few nails.

Tool Box

This tool box is made from Ash from our hedgerows and local oak. It is built using traditional design and joints. The beauty about this tool box is that it can be made to measure and I have fitted it out specifically for my better wood working tools.

The casket is ash with an oak handle profiled to hand and fitted with a 8mm stud hidden and tapped into the ends.